Steer-by-wire (SBW) systems demonstrate the limits of conventional vehicle development. Eliminating mechanical connections opens up new degrees of freedom in design and functionality, especially for electric vehicles and modern driver assistance systems. At the same time, this technology requires comprehensive validation and verification of safety, driving comfort, and system integration. The complexity, high safety requirements, and precise coordination of steering feel and driving dynamics make conventional tests expensive, time-consuming, and difficult to scale. Fast, safe, reliable, and reproducible test methods are therefore more crucial than ever. This is exactly where the SBW-in the-Loop test system from IPG Automotive comes in.

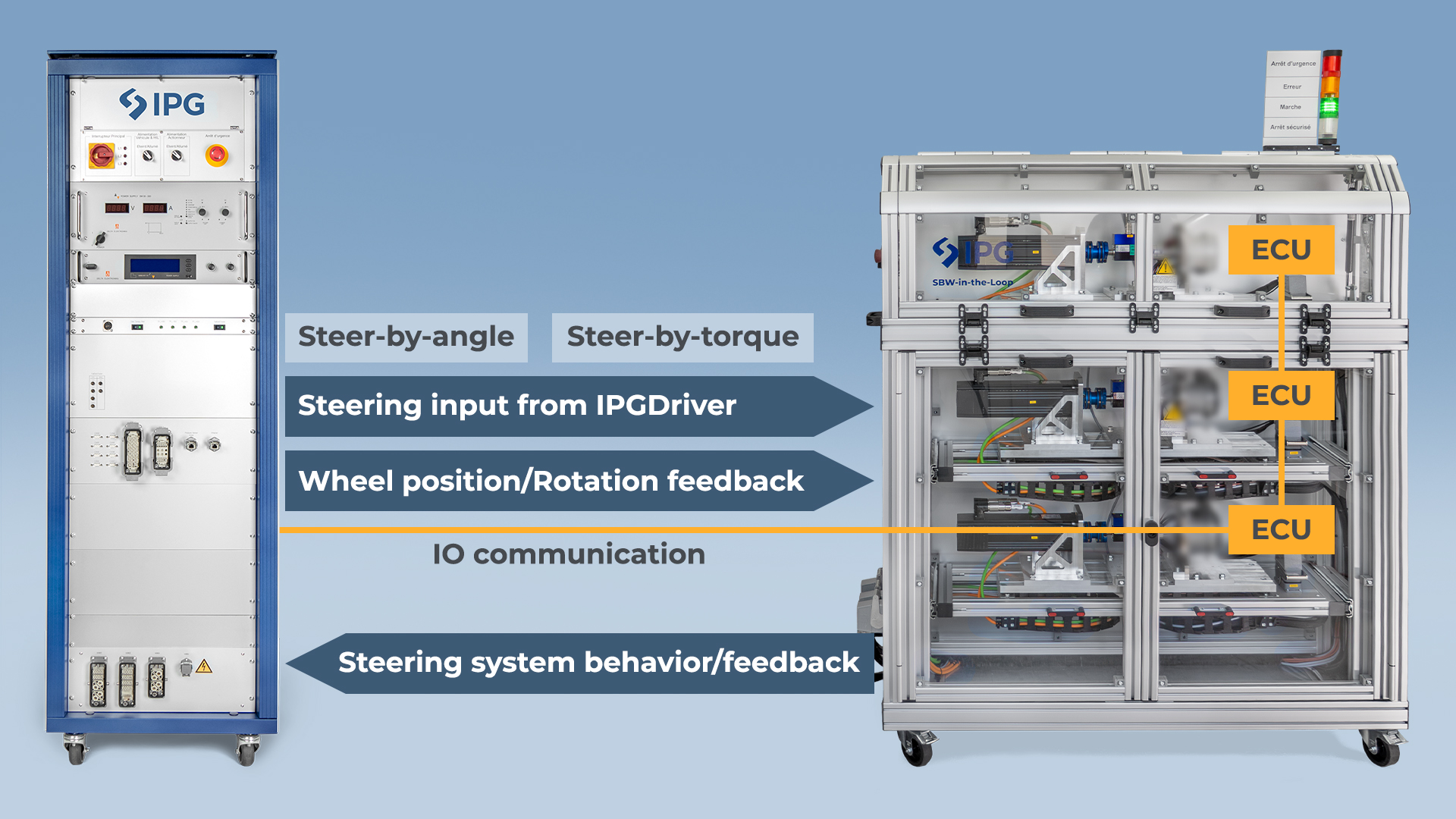

It allows control units to be validated and calibrated at an early stage. The system under test (modular powerpack including ECU and motor) is combined with virtual models of the steering rack, vehicle, and driver, reducing time, costs, and effort. This allows the steering system software and electronic components to be developed and validated early in the process.

Physical and virtual components combined

The test system combines real steering actuators with a highly detailed virtual vehicle environment in CarMaker. Whereas all components must be physically present in conventional test systems, in this case, only decisive elements such as the steering wheel and rack actuators are real, while the rest of the vehicle is represented virtually. This allows driving situations to be simulated accurately and all relevant system parameters, from tire forces and chassis dynamics to the steering wheel (or steering feel or resulting torque), including driver assistance functions, to be tested in an integrated manner.

Direct, intuitive steering feel

A key objective is to optimize steering performance: Steering should feel direct, with no noticeable delay and clear feedback from the steered wheels. This allows the driver to react intuitively. The test system can be used to systematically optimize comfort, safety, and dynamic handling, as well as to check the steering calibration under reproducible conditions.

Flexible, scalable, efficient

The test system can be set up quickly and adapted for different vehicles. The combination of virtual and physical components allows for maximum test coverage and targeted verification of safety functions and redundancy paths. Developers receive timely feedback, can analyze errors, and can implement adjustments efficiently without the need for expensive re-integrations at vehicle level. At the same time, simulation can be used to optimize the control unit for different vehicles and driving conditions. This leads to noticeable savings in time and costs. In addition, the SBW-in-the-Loop test system can be combined with other test systems to efficiently cover system integration tests as well.

From development to release

The test system supports all stages from design to validation to approval. Critical test scenarios, fail-operational and fail-safe tests, as well as different driving modes can be carried out under safe laboratory conditions. This creates a continuous validation process that increases efficiency, maximizes test coverage, and ensures brand-specific steering experience.

Conclusion

IPG Automotive's SBW-in-the-Loop test system combines physical actuators with a virtual vehicle environment without relying on mechanical components and couplings. This allows steering performance, safety, and driving comfort to be tested efficiently, while making the development of steer-by-wire systems faster, safer, and increasingly reproducible.